WIIBOOX®SLM150 METAL 3D PRINTER

High speed · High precision · High quality

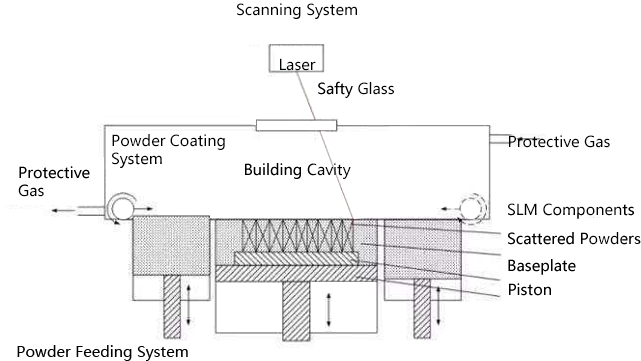

Technical Principle

SLM printing uses selective laser melting technology which melts metal powders and solidifies layer by layer until a three-dimensional part is built. During the process, the ruler in the build chamber will pave one layer of the metal powder, a high powered laser selectively fuses the powder by tracing cross-section of the part on the surface of a powder bed and then a new coat of material is applied for the next layer. The whole process is in a high vacuum chamber or full of protective gas chamber to avoid the metal powder reacts with oxygen at high temperature.

Technological Superiority

Wiiboox is using a high energy and fine spot laser, The equipment can complete complex parts in a very short period time while using conventional methods that will take several weeks or even months to complete in comparison. Parts not only have precise dimension, high tensile and high density, but also excellent in mechanical properties. Mainly used for rapid production of high-precision, high quality metal parts.

Multiple Printing Materials

Wiiboox SLM150 Metal 3D Printer supported printing materials: Stainless steel (316L), Aluminium alloy (AlSi10Mg), Titanium alloy (TC4), Cobalt chromium alloy (MP1), Die steel (MS1), Superalloy (IN718), High conductivity copper (QCr1) etc.

-

Die steel H13

Industrial components

-

Cobalt chromium alloy

Industrial components

-

Nickel base alloy powder

Industrial components

-

Aluminum alloy

Industrial components

-

Titanium alloy

Industrial components

-

Aluminum alloy

Ornament

Customer Cases

Wiiboox SLM150 Metal 3D Printer can print metal parts with complex structure to help shorten product development cycle and reduce R & D cost.

-

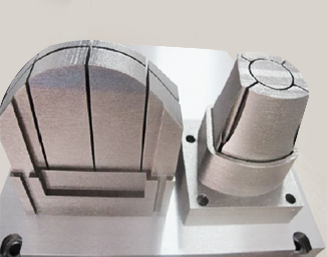

Printing Material: Die steel H13

Printing Size: 210X140X160mm

Printing Size: 210X140X160mm

Printing Technology: SLM

Printing Technology: SLM

Problems to be Solved: solving the problem of thermal stress concentration of injection parts to improve the precision, so as to further improve the life of the mold.

Problems to be Solved: solving the problem of thermal stress concentration of injection parts to improve the precision, so as to further improve the life of the mold.

-

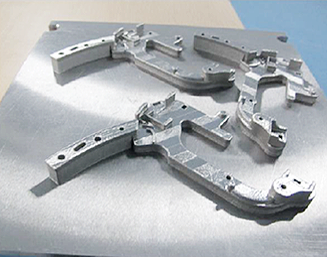

Printing Material: Stainless steel 316L

Printing Size: 180X130X180mm

Printing Size: 180X130X180mm

Printing Technology: SLM

Printing Technology: SLM

Problems to be Solved: shortening the R & D cycle and acquiring more accurate test result.

Problems to be Solved: shortening the R & D cycle and acquiring more accurate test result.

-

Printing Material: Copper alloy

Printing Size: 220X220X100mm

Printing Size: 220X220X100mm

Printing Technology: SLM

Printing Technology: SLM

Problems to be Solved: good density and good mechanical properties, no need of post-treatment process.

Problems to be Solved: good density and good mechanical properties, no need of post-treatment process.

-

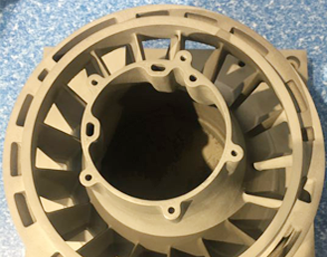

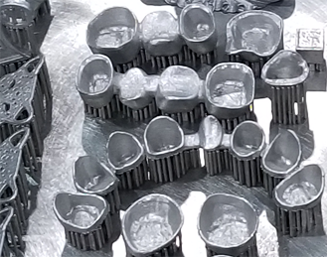

Printing Material: Cobalt chromium alloy

Printing Size: 300X300X80mm

Printing Size: 300X300X80mm

Printing Technology: SLM

Printing Technology: SLM

Problems to be Solved: suitable for customization of single piece or small batch of functional parts.

Problems to be Solved: suitable for customization of single piece or small batch of functional parts.

14F, Building 4, No. 12 Mozhou East Road, Nanjing, China

14F, Building 4, No. 12 Mozhou East Road, Nanjing, China