WIIBOOX SLM250

METAL 3D PRINTER

Security High Printing Accuracy Easy Operation

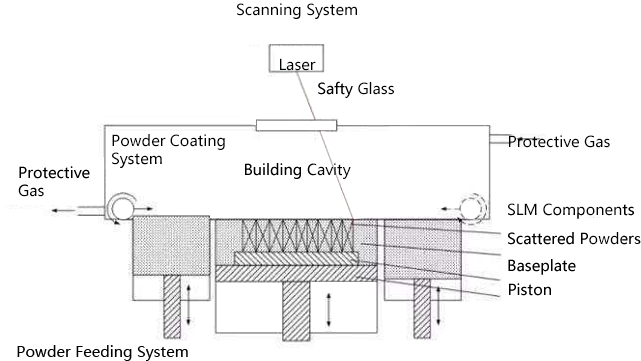

Working Principle

Under the irradiation of high density laser energy, metal powders can be completely melted. After cooling, they can be shaped and welded. It is through this process that SLM technology forms the 3d model layer by layer.

Security

Multiple precaution system protects both human and machine. Sealed work chamber and elastic sealing device with floating balance force protect the printing stability and safety, especially when printing active metal materials.

High Printing Accuracy

Small laser facula and thin layer thickness guarantee more precise printing accuracy. Unique scanning-path and oxygen monitoring system ensure high printing performance. Choose different scrapers according to different printing materials and printing requirements.

Easy Operation

Free Opening of the core technical parameters of the building process. Online real-time modification of the printing & material parameters. Intelligent powder coating method highly saves the printing time. Faster scanning speed ensures printing efficiency.

Multiple Printing Materials

Wiiboox SLM250 Metal 3D Printer can print stainless steel, die steel, cobalt chromium alloy, titanium alloy, aluminum alloy, copper alloy, nickel base alloy powder, etc.

-

Die steel H13

Industrial components

-

Cobalt chromium alloy

Industrial components

-

Nickel base alloy powder

Industrial components

-

Aluminum alloy

Industrial components

-

Copper alloy

Jewelry

-

Stainless steel

Arts and Crafts

Customer Cases

Wiiboox SLM250 Metal 3D Printer can print metal parts with complex structure to help shorten product development cycle and reduce R & D cost.

-

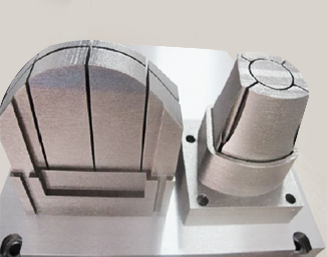

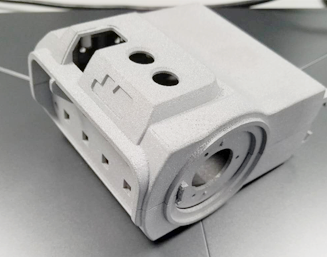

Printing Material: Die steel H13

Printing Size: 210X140X160mm

Printing Size: 210X140X160mm

Printing Technology: SLM

Printing Technology: SLM

Problems to be Solved: solving the problem

of thermal stress concentration of injection

parts to improve the precision, so as to further improve the life of the mold.

Problems to be Solved: solving the problem

of thermal stress concentration of injection

parts to improve the precision, so as to further improve the life of the mold.

-

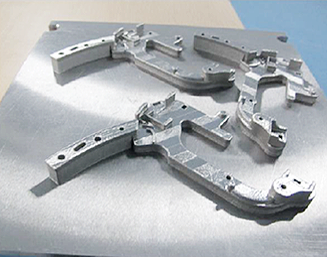

Printing Material: Stainless steel 316L

Printing Size: 180X130X180mm

Printing Size: 180X130X180mm

Printing Technology: SLM

Printing Technology: SLM

Problems to be Solved: shortening the R & D cycle

and acquiring more accurate test result.

Problems to be Solved: shortening the R & D cycle

and acquiring more accurate test result.

-

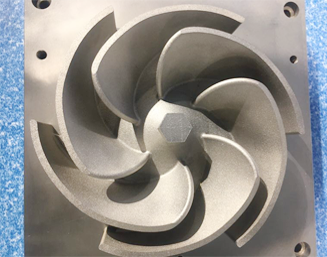

Printing Material: Copper alloy

Printing Size: 220X220X100mm

Printing Size: 220X220X100mm

Printing Technology: SLM

Printing Technology: SLM

Problems to be Solved: good density and good

mechanical properties, no need of post-treatment

process.

Problems to be Solved: good density and good

mechanical properties, no need of post-treatment

process.

-

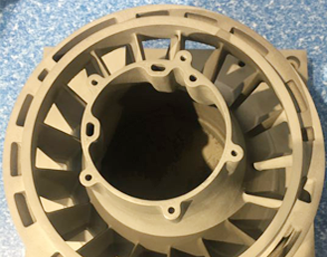

Printing Material: Aluminum alloy

Printing Size: 120X130X220mm

Printing Size: 120X130X220mm

Printing Technology: SLM

Printing Technology: SLM

Problems to be Solved: elimination of

intermediate processes, simplified production process.

Problems to be Solved: elimination of

intermediate processes, simplified production process.

-

Printing Material: Cobalt chromium alloy

Printing Size: 300X300X80mm

Printing Size: 300X300X80mm

Printing Technology: SLM

Printing Technology: SLM

Problems to be Solved: suitable for

customization of single piece or small batch of functional

parts.

Problems to be Solved: suitable for

customization of single piece or small batch of functional

parts.

-

Printing Material: Titanium alloy

Printing Size: 300X300X80mm

Printing Size: 300X300X80mm

Printing Technology: SLM

Printing Technology: SLM

Problems to be Solved: The printed parts have

better surface quality and accuracy even without

polishing.

Problems to be Solved: The printed parts have

better surface quality and accuracy even without

polishing.

14F, Building 4, No. 12 Mozhou East Road, Nanjing, China

14F, Building 4, No. 12 Mozhou East Road, Nanjing, China